A Gstaad invention

19.08.2019 Gstaad LivingFor amateur skiers, there’s nothing better than taking the first gondola and gliding over a freshly prepared slope. However, steep slopes could not be prepared with precision until the 1980s. Wild mogul runs were the result. Then, cable winch technology was adapted to suit snow groomers.

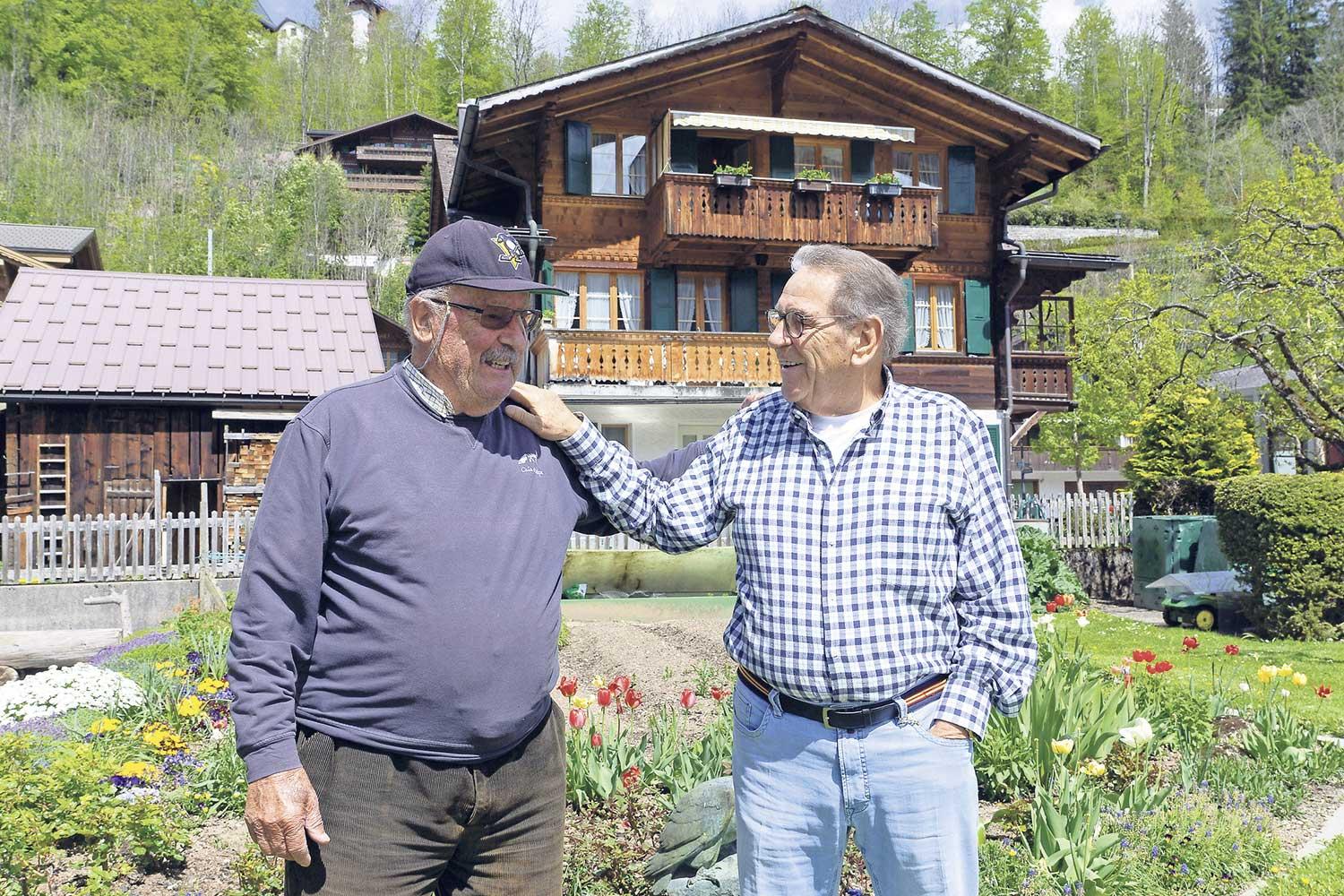

This technology helps to smooth out steep slopes and give them the perfect furrows. Who invented winch technology for snow groomers and similar types of machinery? Well, it was a case of teamwork: Konrad Brand, head of technology at the Wasserngratbahn and Fred Rölli, owner of the Fred Rölli Garage, were the creative inspiration behind the invention. Engineer Wiederkehr from Plumettaz AG, Mr Brändli, BIBUS Hydraulik AG and the company Gebrüder Würsten in Gstaad were also on board with the project.

The solution: The winch in a central position

Ernst Andrea Scherz remembers well the 1983 Saturday night meeting in the bar of the Olden. “I asked Fred Rölli for ideas on how to make the Wasserngrat slopes more attractive in winter.” At that time, Scherz was president of Wasserngrat AG and was looking for additional sources of revenue: “Back then, the chair lift was always on unsteady ground financially.”

Rölli was well aware that some of the appealing ski slopes on the Wasserngrat were too steep for slope preparation and, therefore, only used as demanding mogul runs. He recommended to Scherz that the slope, later known as the Tiger Run, should be mechanically prepared. He also came up with the idea of the winch technique, which was also used in tanks and jeeps. These were also the thoughts of Brand, who had been dealing with the topic for many years. Tests showed how difficult it was to prepare a slope to a high standard using a winch.

First, the team pursued the idea of mounting a stationary winch on the site. However, this was quickly dismissed because there were too many uncertainties. Employees would need to stand nearby to operate the machine. Also, the costs would be very high. In addition, it was feared that the winch was not as fast as the snow groomer, resulting in constantly fluctuating pulling forces. Finally, communications between the Pistenbully driver and the winch operator would have presented a challenge.

A second variant was to attach the winch directly to the vehicle, either at the front or rear, but too many uncertainties surrounded this. It was clear that this method would have rendered the snow groomer impossible to steer. Only one slope section could have been prepared before needing to hook the rope onto a new anchor point.

After much fiddling around, it turned out that the winch had to be fixed in the centre of the snow groomer. This meant the vehicle was always steerable, even when secured with the rope.

Tinkering about

Rölli put in a good word to Scherz about the credit for the development. After some to-ing and fro-ing, Wasserngrat AG secured a budget of CHF 30,000. Immediately, Rölli and Brand ordered a winch with 400 metres of rope, equipped to support two tons in weight.

The next challenge was the operation of the winch. Like caterpillars and snow blowers, a winch is hydraulically controlled. But how do you make sure that the cable has an equal pulling force at all speeds? The mooring system used in shipping solved this issue. “This system is highly sophisticated and was recommended to me by a technician from BIBUS Hydraulik AG,” recalls Brand. After the chief engineer had received the plans more tinkering and building followed.

Assembling the puzzle

The framework for attaching the winch and other elements was produced by the Gebrüder Würsten in Gstaad. Assembly was carried out by Brand along with structural mechanic, Michael Perreten. “I was quite nervous on our maiden voyage,” admits Brand, adding that his uncertainties were not only down to the new technology: “The winch was delivered without an emergency brake!”

In truth, Brand had made several attempts to have the emergency brake fitted before the winter season, but this didn’t happen for various reasons. So, he prepared what was then the steepest slope in the Saanenland without an emergency brake.

To reflect the thrill of the downhill run, the slope was named the Tiger Run. For a long time, it was considered to be one of the Saanenland’s major attractions.

Sold too cheaply

News about the new invention spread quickly. Engineers and slope managers from far away visited the Wasserngrat to see the global novelty. It didn’t take long for the competition to start. By the following winter, the Schilthorn had already used the new technology.

Brand helped with the construction of the second prototype. Wasserngrat AG received CHF 50,000 for this. “This money was worth its weight in gold and helped our struggling finances,” said Scherz, looking back. Rölli regretfully adds: “We would have been better negotiating a piecemeal contract rather than a lump sum. We’d have been made today!”

At a media conference, the Schilthorn presented the novel technology to a large audience. According to Brand, the then CEO of Kässbohrer said: “The system will never survive!” Nevertheless, the manufacturer jumped on the opportunity. “Just one year later, a series of four was produced and three years later, a series of 40,” recalls Brand. Rölli wanted to patent the invention, but this wasn’t successful, because parts that already existed were involved. So, the technology invented in Gstaad is now used by all snow groomer manufacturers around the world.

Based on AvS/Blanca Burri

Translated by Justine Hewson